“Every connection point is a weak point”

Written by Olufemi/Adeteju

In a PV system, every connection point is a recipe for disaster. At Sunhive, we recognise that implementing the best safety practices is paramount to avoiding catastrophes.

After the installation and commissioning of a PV system, faults can occur anywhere on the DC cabling that runs from the solar modules to the inverters and charge controllers; as well as other connections to the batteries. There are about 45 connection points in the DC circuit of a small solar system (3kW) and about 60 connection points in a 5kW system. All of these connection points undertaken by the solar installer is a potential point of failure.

The temperature of a DC fire of a typical PV system is easily hot enough to melt glass, copper, and aluminium, and to initiate the combustion of surrounding materials.

Remains of a DC Isolator inspected in the laboratory (The fire investigations (UK) LLP)

The Uniqueness of DC fire/Arcs

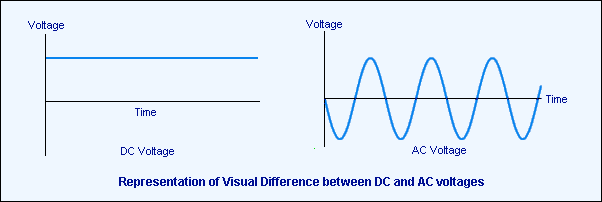

For an arc to be self-sustaining, the conditions for starting the arc must be present continuously. DC remains at a continuous voltage and once an arc has been established, it will continue as long as the DC voltage is present.

Arcing is less of an issue in AC systems because AC arcs tend to self-extinguish as the voltage alternates, passing through 0 volts one hundred times per second for standard grid supplies.

The likelihood of a DC fire/arc fault increases with the age of the installation. This is because joints in the DC wiring corrode over time increasing the impedance, causing heat and the breakdown of the continuity of the joints resulting in a DC arc fault. Also, seals on isolators, conduits etc degrade over time allowing water ingress which can cause a DC arc fault.

Rodents, insects, birds can damage or degrade insulation over time.

Root cause of PV fires/DC arc faults

The Building Research Establishment centre, National Solar Center conducted research to ascertain the root cause of PV fires and DC arc fault, they were summarized into three:

- Error in system design

- Faulty Product (Quality Issue or Product design issue)

- Poor installation practises.

It was deduced from the three that 72% of the occurrence was as a result of poor installation practice, 22% from Faulty product and only 6% from error in system design. It is clear that installers should be required to demonstrate the required level of competency and compliance before being passed to work on a solar system.

The best installers in the world can make mistakes occasionally and these mistakes could create a sequence of unfortunate events with catastrophic consequences. This means rigorous commissioning and inspection regimes must be put in place to mitigate the risks of PV fires.

Generally, PV systems are very safe and maintenance plans must be rigorous even though there is no maintenance plan, no matter how comprehensive, that could potentially check all the weak points in a solar system.

The installation phase is key to getting it right.

Weak points in solar installations.

Special care and attention should be taken with respect to selection, installation, and maintenance of several significant points of weakness in a solar installation.

- DC Isolators/Junction Boxes: They were found to present the greatest fire risk in all incidents database.

Special care must be taken during selection, wiring and torquing. The general installation instructions from manufacturers must be followed.

- Mc4 Connectors: The use of dissimilar Mc4 from different manufacturers will, inevitably, increase the risk of arcing in the circuit due to the low intermateability of the Mc4s.

Most importantly, installers have not been using the proper tools to crimp the metal insert resulting in arcing and localized heat rise. The most commonly used MC4 style connectors require the use of custom crimping tools to ensure the integrity of the connection.

- Inverters: Incidents are mostly not caused by Inverters. most times, incidents with inverters are caused by the failure of the surrounding components.

However, they should be properly selected with respect to system requirements, the load-bearing capacity should never be exceeded. Voltage limits should also be well respected.

- PV Modules: Like the inverters, the module limits should never be stretched. Proper selection and good installation procedures and standards should be followed.

- Conduits and cables:

Water ingress can cause degradation of seals and eventually contacts between the conductors, cable ratings, size and standards must be checked before a selection is made.

- Grounding: A PV system, just like any electrical system, must be provided with a grounding system coordinated with appropriate safety devices for protection against indirect contact. The layout of the grounding system varies depending on the type of plant and application standards with the type of installation.

With the rapid increase in the number of installations comes an inevitable increase in the number of faults, with the potential to cause fire.

Always make sure not to create a weak link, or be the weak link.